Cold Chain Technology: Maintaining Food Freshness in Supply Chains

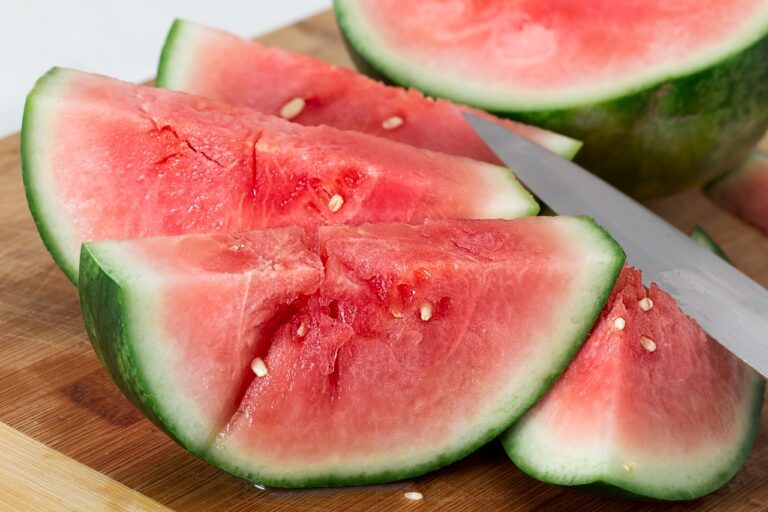

One of the critical factors in the food industry is maintaining the freshness of food throughout the supply chain. From farm to table, ensuring that food remains fresh is essential for both food safety and quality. Freshness not only impacts the taste and nutritional value of food but also plays a vital role in reducing food waste.

In supply chains, maintaining food freshness involves implementing proper storage and transportation practices. This includes controlling temperature, humidity, and handling processes to prevent food spoilage. By prioritizing the preservation of food freshness, businesses can uphold their reputation, meet regulatory requirements, and ultimately satisfy consumer preferences for high-quality, fresh products.

Understanding the Role of Temperature Control in Cold Chain Technology

Temperature control plays a crucial role in maintaining the integrity of products throughout the cold chain. Maintaining consistent temperature levels is essential in preserving the quality and safety of perishable goods as they move through various stages of the supply chain. Even slight deviations from the optimal temperature range can lead to spoilage, contamination, or reduced shelf life of products.

Cold chain technology relies on the effective management of temperature, ensuring that goods are kept within the recommended temperature range from production to distribution. By utilizing specialized refrigeration systems, monitoring devices, and insulated packaging, companies can mitigate the risks associated with temperature fluctuations and uphold the freshness of their products. Proper temperature control not only safeguards the quality of goods but also helps in minimizing food waste and enhancing consumer satisfaction.

Key Components of an Effective Cold Chain System

One essential component of an effective cold chain system is proper packaging. Ensuring that the packaging materials used are designed to maintain the desired temperature range is crucial in preserving the quality and safety of perishable goods throughout the supply chain. Insulated materials and advanced packaging technologies play a vital role in protecting products from temperature fluctuations during transportation and storage.

Another key component is reliable monitoring and tracking systems. Real-time monitoring of temperature conditions along the supply chain allows for immediate corrective actions to be taken in case of any deviations. These systems help to identify areas of improvement and ensure that products remain within the required temperature range, preventing spoilage and maintaining product integrity until they reach the end consumer.

Proper packaging materials designed to maintain desired temperature range

Insulated materials and advanced packaging technologies crucial for protection

Preserves quality and safety of perishable goods throughout supply chain

Reliable monitoring and tracking systems essential component

Real-time monitoring of temperature conditions allows immediate corrective actions

Identifies areas of improvement and ensures products remain within required temperature range

What is a cold chain system?

A cold chain system is a series of temperature-controlled processes and logistics involved in the transportation and storage of perishable goods to maintain their freshness and quality.

Why is maintaining food freshness important in supply chains?

Maintaining food freshness is crucial in supply chains to ensure that products reach consumers in optimal condition, reduce food waste, and enhance food safety.

What is the role of temperature control in cold chain technology?

Temperature control is essential in cold chain technology to regulate and maintain the temperature of perishable goods throughout the supply chain, from production to consumption, to prevent spoilage and ensure quality.

What are the key components of an effective cold chain system?

The key components of an effective cold chain system include temperature monitoring devices, refrigeration units, insulated packaging, proper handling procedures, and trained personnel to ensure the integrity of perishable goods.

How can businesses benefit from implementing an effective cold chain system?

Businesses can benefit from implementing an effective cold chain system by reducing product losses, improving product quality, increasing customer satisfaction, and complying with food safety regulations.